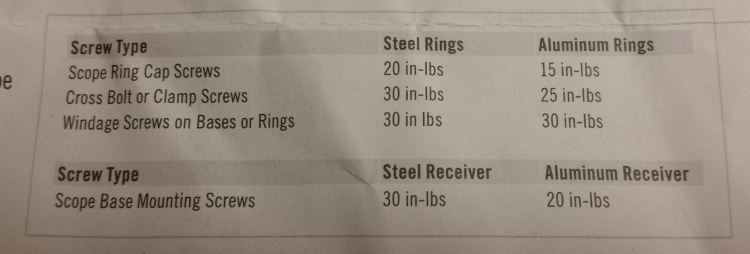

In case you have never seen it, here is Weaver's guidelines for the various screws and mount cross bolts.

Here is a link to a complete detail on the Weaver brand of bases and rings, along with their Simmons and Redfield brands: Weaver Torque Specifications

In the past, I've been pretty good about following suggested specs and even have torque screwdrivers and wrenches. I don't have a place to get these devices certified anymore and I knew my rather high dollar driver had somehow gotten out of spec, so I've been tightening screws my feel. Where this became critical was a mount for my Mini-30 with the weight of the night vision scope. I over tighten the base screws, and they failed. The outfit sent me new screws, and I went ahead and bought a new driver, the Weaver #849728. I added a link to MidwayUSA because I noticed it was on sale! I had considered the Wheeler product as it is about $10 less, but the range is less than the Weaver, it is on sale as well.

What I do to get a true torque on the screws is run them all in and out while in hand. That puts a bit of wear on them and frees them and the hole threads from any mico-burrs that might exist. Sometimes the base screws come with a thread locker, so you are wearing through that, but that "locker" in its dried state is going to influence the torque of a screw and the value will come up short on the in/lbs. I reapply Loctite blue or red if specified I've, but use the blue if neither is stated.

Blue can be removed with hand tools. Red has screwed up a high percentage of the screws it has secured because people don't know how to remove it. It needs heat. The best way I know to overcome the bond of red is to heat the driver to be used with a propane torch until it glows, touch it to the screw head and let it set a few seconds to transfer the heat, and then tap the driver with a small hammer to shatter the seal. The red must be heated to 500°C to be removed to prevent damage to the screw or attach holes.

Ahhh, don't use a torque driver to remove screws!