I won't go through the math at this time, but the force of the spring clip is orthogonal to the force of the ram. Therefore, the horizontal force of the spring clip is significant relative the horizontal component of the vertical ram force...Fyodor wrote:Yes, but the spring clip is insignificantly weak in comparison to the ram force. So if it isn't concentric, and it will free float to the correct position with the O-ring, it will free float with the spring clip, too. The clip isn't limiting the range of movement. it just gives a little more resistance.

Free Float Press Shellholder

- buckeye43210

- 250 Shots

- Posts: 253

- Joined: 20 Dec 2014 09:47

- My Press Choice: Progressive

- Location: TPA

- Has thanked: 23 times

- Been thanked: 131 times

Re: Free Float Press Shellholder

- Macd

- Supporter

- Posts: 1009

- Joined: 16 Oct 2017 16:12

- My Press Choice: Single Stage

- Location: Far East

- Has thanked: 362 times

- Been thanked: 403 times

Re: Free Float Press Shellholder

Geewiz buckeye, now my head hurts. :p

My take, and I may be wrong, is if there is sufficient play in the shell holder's fit in relation to the slot in the ram it should be able to orient to the centre and the angle of the die. In other words if the die is not perpendicular to the slot the case should move the shell holder to the proper orientation as it enters the die. The fly in the ointment, in my experience, is often the shell holder is a tight fit and is limited in its ability to reorient. This exacerbates any other misalignment such as die axis to ram axis or the slot or die base to the surface of the shell holder. Add a tight fitting case rim and things just get worse. I believe the spring should not grip the shell holder but just loosely keep it in the ram slot. As soon as the play that allows self adjustment is removed from the equation then alignment tolerances become critical. This makes manufacturing much more difficult and expensive.

My take, and I may be wrong, is if there is sufficient play in the shell holder's fit in relation to the slot in the ram it should be able to orient to the centre and the angle of the die. In other words if the die is not perpendicular to the slot the case should move the shell holder to the proper orientation as it enters the die. The fly in the ointment, in my experience, is often the shell holder is a tight fit and is limited in its ability to reorient. This exacerbates any other misalignment such as die axis to ram axis or the slot or die base to the surface of the shell holder. Add a tight fitting case rim and things just get worse. I believe the spring should not grip the shell holder but just loosely keep it in the ram slot. As soon as the play that allows self adjustment is removed from the equation then alignment tolerances become critical. This makes manufacturing much more difficult and expensive.

- Fyodor

- Founding Member & Supporter

- Posts: 1512

- Joined: 04 Jan 2014 05:45

- My Press Choice: Progressive

- Location: Gernsbach, Germany

- Has thanked: 794 times

- Been thanked: 504 times

Re: Free Float Press Shellholder

You forgot, that if it was like that, even an air bearing would be immovable, because the vertical ram movement has no horizontal component at all.buckeye43210 wrote:Therefore, the horizontal force of the spring clip is significant relative the horizontal component of the vertical ram force...

But there is the shell that has some angular degree of freedom. A slightly canted case acts as a tilted plane type lever with a brutal gear ratio. That vertical component gets translated to a manyfold horizontal force.

"I disapprove of what you say, but I will defend to the death your right to say it"

- Evelyn Beatrice Hall, often misattributed to Voltaire

I think I'm thinking, therefore I may possibly be.

- Evelyn Beatrice Hall, often misattributed to Voltaire

I think I'm thinking, therefore I may possibly be.

- EdgeOfEden

- Posts: 82

- Joined: 29 Apr 2018 16:23

- My Press Choice: Progressive

- Location: TN

- Has thanked: 23 times

- Been thanked: 39 times

Re: Free Float Press Shellholder

While interesting to read, I'm not exactly sure why this is being debated when there is already demonstrative evidence that a free floating shell holder aids in reduced bullet run out while seating. How many measurements have to be done before we are convinced? It's like debating on whether or not the Bernoulli Principle can explain why an airplane flies, when in fact it flies. If the Bernoulli Principle is false, the plane doesn't go up. As a layman, I can be happy knowing the airplane will fly even if I don't understand why. Likewise I don't have to understand the various geometric forces on the case and shell holder to know that a free floating shell holder does indeed lower bullet run out. A press that has perfect alignment likely won't benefit much, but if the ram axis is slightly off (for whatever reason), a free floating shell holder will make a difference.

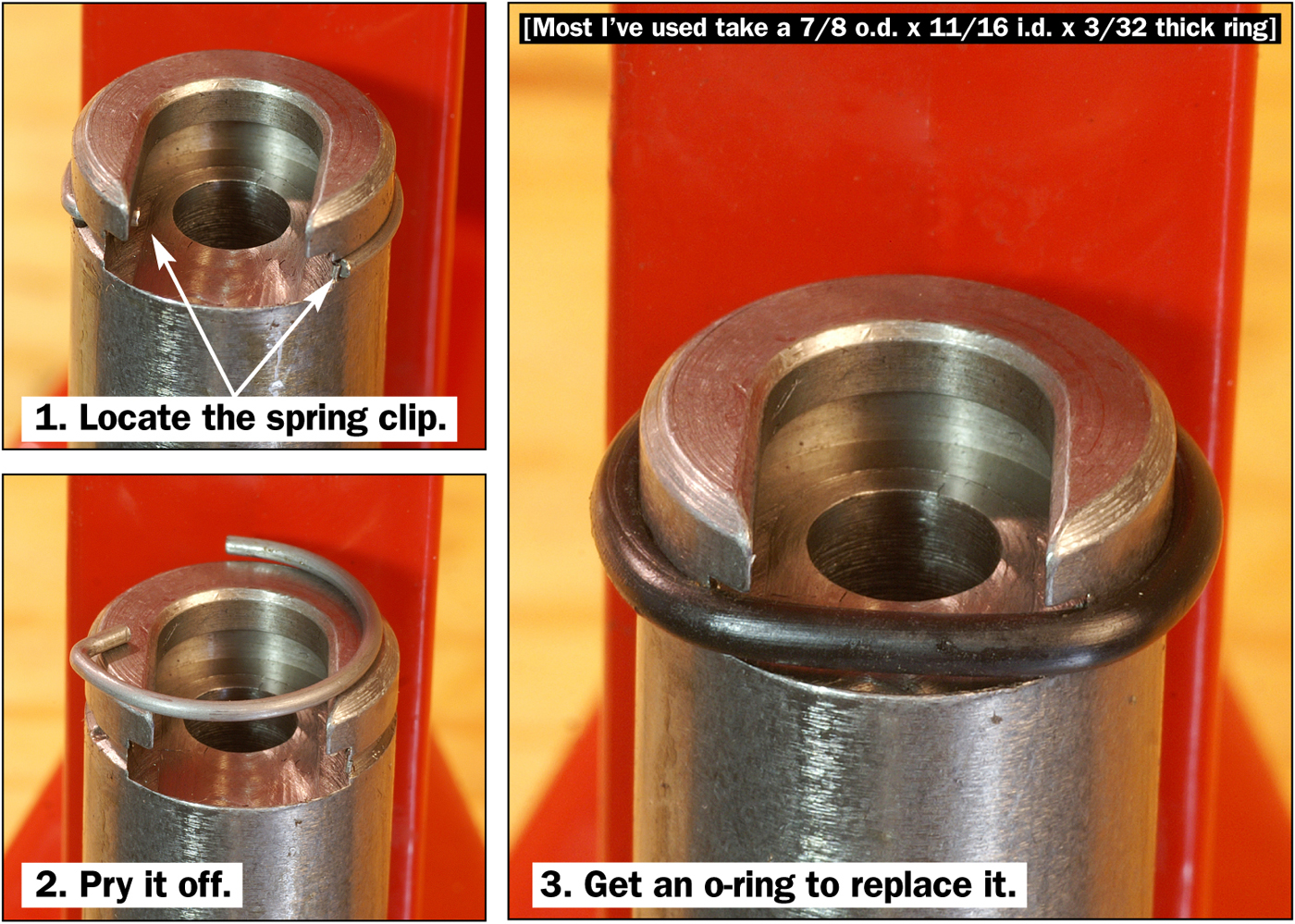

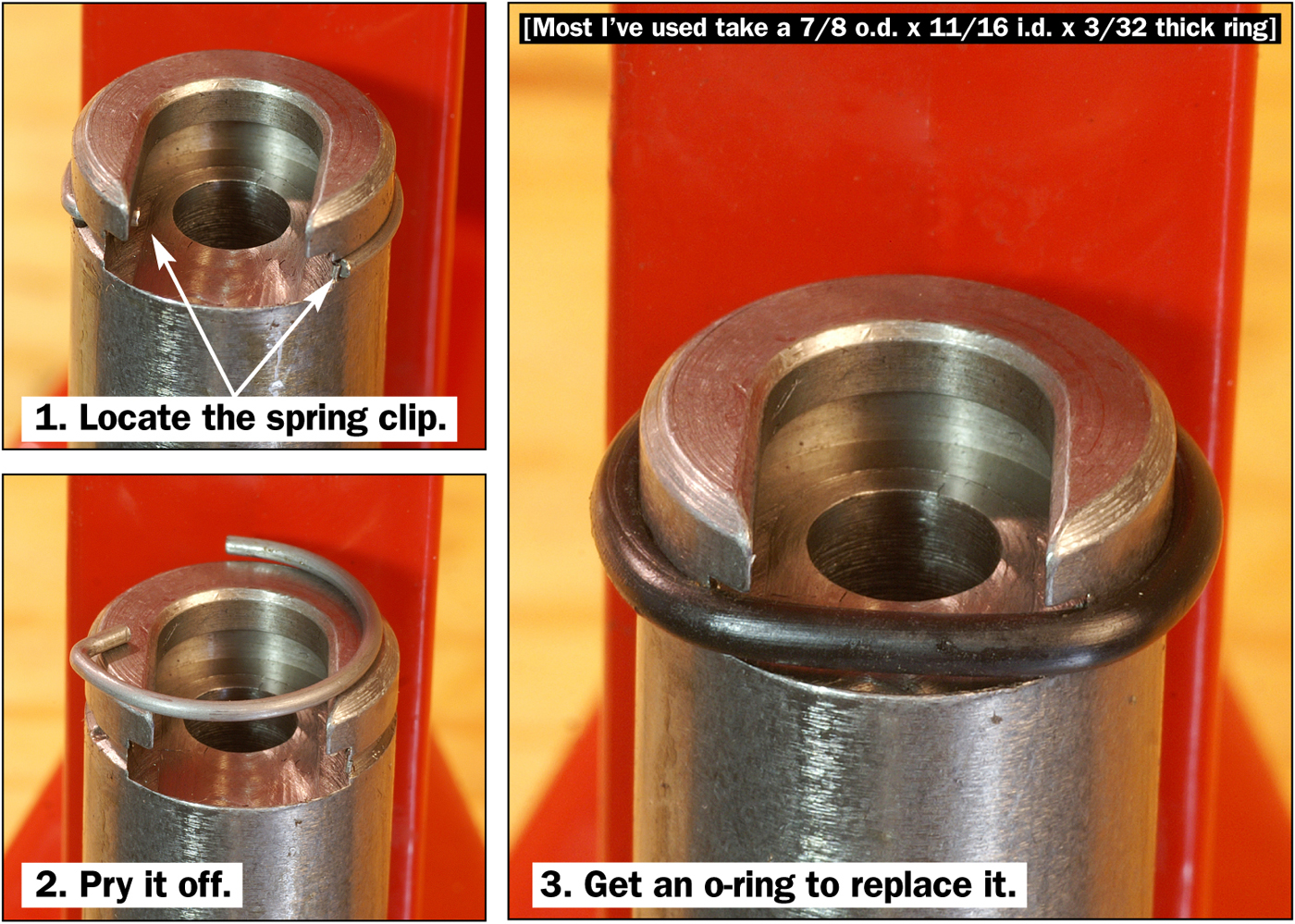

Why do you think so many spend big bucks for the Forster Co-Ax and some are now thrilled to have the less expensive MEC Marksman? Again, for the average shooter, this difference will likely mean nothing, but for the long distance shooter every advantage matters. I'm content just to add an O-Ring to my Lee Classic Cast Breech Lock when I start loading for my 6.5 Creedmoor bolt action.

Why do you think so many spend big bucks for the Forster Co-Ax and some are now thrilled to have the less expensive MEC Marksman? Again, for the average shooter, this difference will likely mean nothing, but for the long distance shooter every advantage matters. I'm content just to add an O-Ring to my Lee Classic Cast Breech Lock when I start loading for my 6.5 Creedmoor bolt action.

- Et2ss

- Moderator & Supporter

- Posts: 143

- Joined: 18 Nov 2018 19:56

- My Press Choice: Progressive

- Location: Far too close to the edge

- Has thanked: 4 times

- Been thanked: 68 times

Re: Free Float Press Shellholder

The priginal pic didn't show for me so I found one on the webz, and uploaded it to my server. Hopefully this shows for everyone

- daboone

- Founding Member

- Posts: 1397

- Joined: 30 Nov 2013 21:47

- My Press Choice: Single Stage

- Location: AZ, TX, HI

- Has thanked: 677 times

- Been thanked: 787 times

Re: Free Float Press Shellholder

Yep that spring clip canting cases was why I own 4 different shellholder. Couldn't figure it out, just kept get another brand of shellholder without solving the problem. Now I don't own a press that accepts shellholders. I like free floating shell plates and lee dies because they bevel the entrance for easy case insertion.

An ignorant person is one who doesn't know what you have just found out.

When setting a job up for myself it must be Idiot Proof as well, as I am a bigger idiot than most people I know, and I prove it to myself everyday.

When setting a job up for myself it must be Idiot Proof as well, as I am a bigger idiot than most people I know, and I prove it to myself everyday.

-

horseman

- Supporter

- Posts: 999

- Joined: 09 Nov 2015 06:35

- My Press Choice: Single Stage

- Location: Washington State

- Has thanked: 37 times

- Been thanked: 274 times

Re: Free Float Press Shellholder

I know the "free float" thing is a big selling point with the co-ax press. I have one and I like it. I also have a Lee Classic Cast SS press. I like it too. For the folks that want to try to make any press "free float" it certainly shouldn't hurt anything, but if you go a bit further into making a case or finished cartridge more concentric, you're going to have to look into better dies. A fired case from your rifle (assuming all is well there) is about as concentric as you can get. The sizing die that can change that. There's a bit more to making "concentric" ammunition than an O ring under the shell holder (or a die) OR just using a co-ax press. It's called case prep. Will it make a difference for most of us, not in my opinion with the rifles we shoot. But it doesn't hurt and it can be not only educational but enjoyable as well. It will also relieve the OCD issues that most of us have in making our finished rounds as consistent as we can, even if it doesn't show on paper. This is just an opinion from another old "curmudgeon" that thinks he knows more about which he speaks than he actually does