Ranch Dog wrote:Made real good progress on this project last night & this morning with the addition of a Pachmayer 750 Decelerator Pad. This added an inch of pull to the length which I really needed. This is the first grind to fit pad I've installed and it went like I was a Pro!

The holes on this stock were really wallowed out so I did it like it is supposed to be done. I drilled them out big time and filled the holes with 3/8" hardwood dowels that I cut off after they dried in place.

The base of the stock was not cut square but I did not want to cut anymore off the stock as the optimal length of pull for me is 15.25". I do not have the big grinding wheels and belts that a gunsmith would use, only a simple 1"X30" belt sander from Harbor Freight that I paid about $25 for once I finished handing them coupons!

To square the very butt of the stock up, I pulled off the safety shield off the top of the sander and just backed the stock into the belt holding it square to the belt until it was true. Worked like a champ and only took a few minutes at the most!

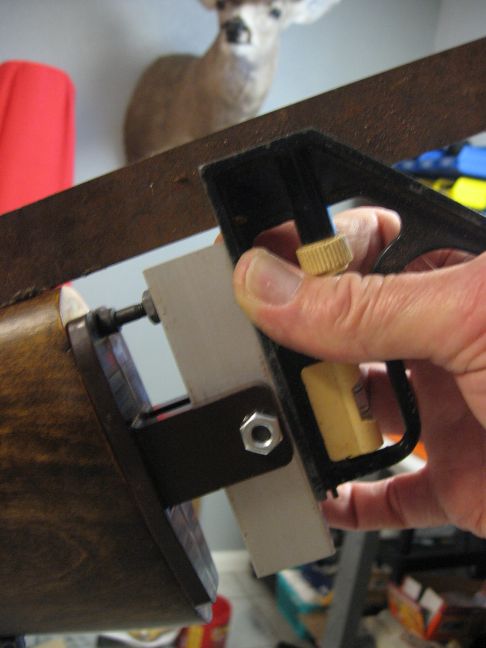

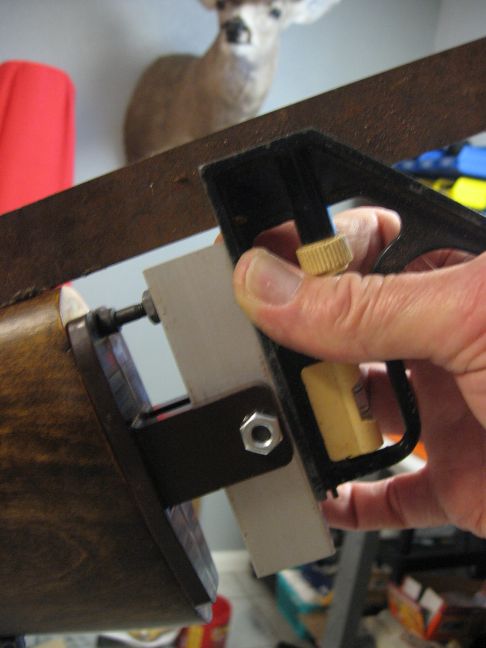

I do have the Pachmayr Recoil Pad Grinding Templates and the Miles Gilbert Recoil Pad Installation Fixture. The templates make lining up the holes and centering the pad a breeze. As this was my first use of the Installation Fixture, it took me awhile to get comfortable with setting it up as once you start grinding you are committed. The old measure a couple of times to cut once.

With the comb and bottom line of the stock set on the Installation Fixture I went right to work. The "Small" Pachmayr 750 is really large on the small stock of the 340 but it grinds quite a bit faster than you would think. The belt sander had an 80 grit belt and the finish on the pad was as smooth as it gets!

Besides the setup instructions, I did follow the advice Mr. Potter gave in a MidwayUSA video on using the tool. The best advice was concerning the use of a scribe line in the pad and then filing a stick of chalk over the pad and wiping the chalk dust off the pad. The scribe line really stands out and you grind right up to the line. It was perfect advice!

The belt sander worked like a charm. It has a vacuum port that kept the debris to a minimum, not like I saw in the video.

Here it is as pretty as can be!

My scope rings came in today's mail so I'm going to work on that now. The Numrich order has been held up due to the weather but I will be ready to go once it is here!