Page 2 of 3

Re: My pot is leaking

Posted: 02 Aug 2016 16:46

by Ranch Dog

GasGuzzler wrote:klr wrote:jloader wrote:Can you elaborate on how you "lap the plunger to the hole"?

Thanks

I put some valve lapping compound where the plunger meets the pour hole and then rotate the plunger.

Like lapping a valve.

At one time I had some pictures of this. I took the valve rod off the pot and kind of polished it up with steel wool. Then I put some lapping compound down in the valve and spun the rod into it where they mate, working it until I felt a fine fit. I cleaned the lapping compound up completely and then applied Permatex Anti Seize #133 to the valve (this is in the Lee instructions that come with the pot). When I bought my second pot, I did this immediately. My original pot went lukewarm on me so I bought the parts to rebuild it and will lap & anti seize it again before I put it back in service. Neither of mine drip and I use the stock handle without additional weight.

Of course the Golden Rule is to never use a production pot as a smelting pot.

Re: My pot is leaking

Posted: 02 Aug 2016 20:23

by Okie44

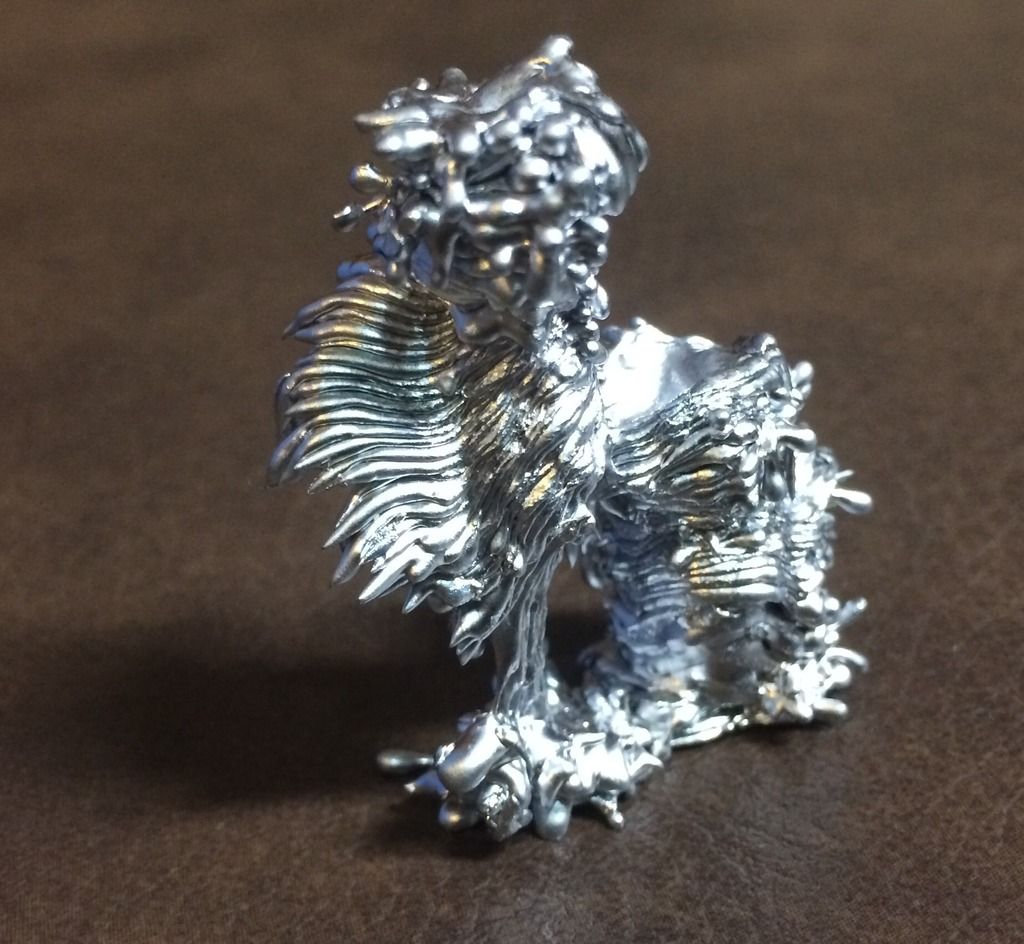

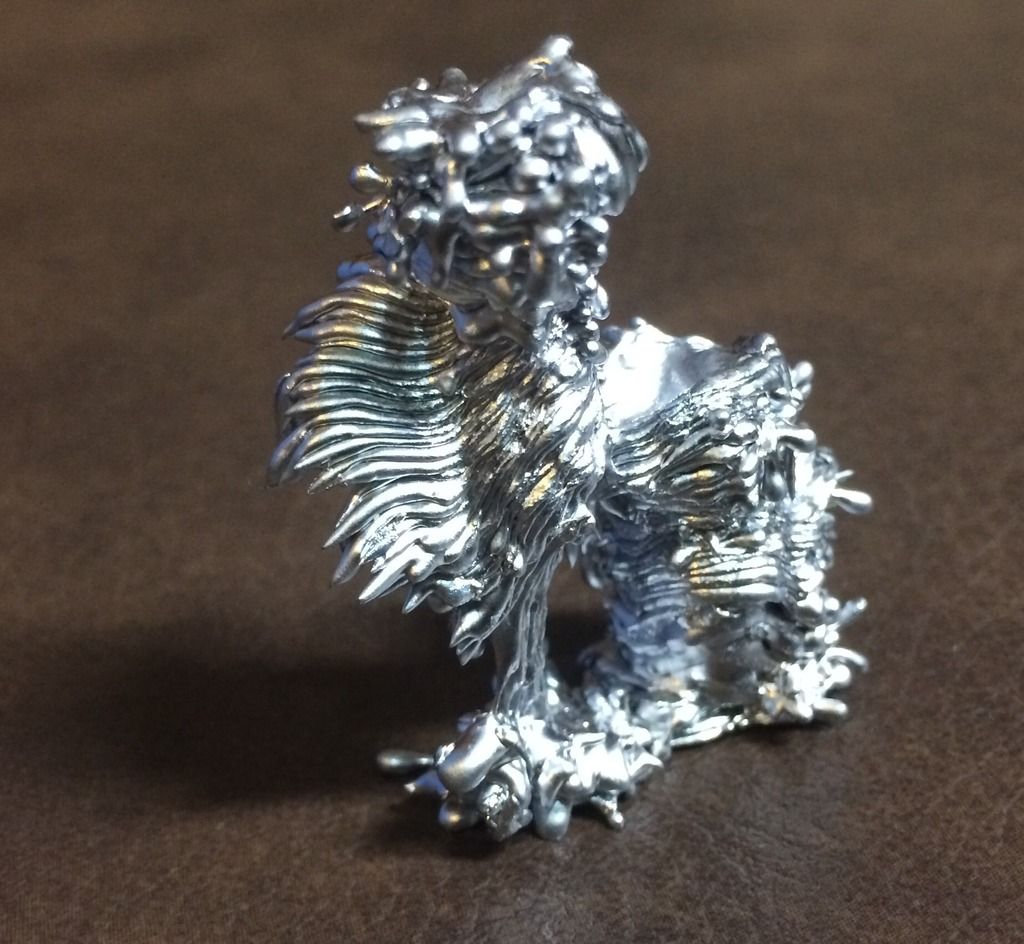

Mine makes cool stuff.

Re: My pot is leaking

Posted: 03 Aug 2016 05:56

by Ranch Dog

I see someone's face in that, I just don't know who's!

Re: My pot is leaking

Posted: 03 Aug 2016 06:27

by jloader

Klr - thanks a million for this simple advice!!!

My pot is now NOT leaking.

Here's what I did:

- heat up the pot and pour out all of the lead

- while the pot was cooling, I unscrewed the plunger retaining screws, removed the plunger and gave it and the pot a scrape with edge of flat screwdriver.

- when it was cool I mounted a flat screwdriver bit into my cordless drill and used it for several seconds to lap the plunger in the spout to get a baseline.

- when I looked at the plunger, you could see a shined up line around it where it made contact with the spout - it was very irregular about 1/16th in the widest

- I put some polishing compound on the tip of the plunger (had some compound in my roto toolkit) and gave it a series of lapping runs at about 2-3 revolutions per second with light to moderate pressure re-adding polishing compound occasionally

- after about 4-5 minutes of this process I took a closer look at the plunger - now I have a consistent 3/16th inch shiny "seat"

- used copper wire (14 gage) to scrape and clean the inside of the spout

- reassembled the pot and heated 3 lbs of lead - no leaks.

Saved me a bundle on shipping and have learned how to address a leak in the future!!!

Re: My pot is leaking

Posted: 03 Aug 2016 07:28

by klr

Great!

Re: My pot is leaking

Posted: 03 Aug 2016 16:27

by GasGuzzler

Nice!

Re: My pot is leaking

Posted: 03 Aug 2016 17:47

by 62chevy

Ranch Dog wrote:I see someone's face in that, I just don't know who's!

Looks like a man climbing a cliff to me.

Re: My pot is leaking

Posted: 04 Aug 2016 22:43

by Old Scribe

Good news!

Re: My pot is leaking

Posted: 05 Aug 2016 07:29

by daboone

Before using using valve grinding/polishing by whatever method be sure to CLEAN the pot. Start by emptying out all the lead. When it's cooled down add tap water and crank it up to full blast and let that water BOIL. Then with a wire brush give it a good scrubbing. Be prepared to be amazed as to how clean it will be. By doing the boiling water clean you avoid all the lead oxide(s) dust when you get down to the polishing of the spout. Better safe than sorry.

Re: My pot is leaking

Posted: 05 Aug 2016 07:35

by jloader

I would love to have been able to do that before lapping, but with the speed at which it leaked, the water would have leaked out before reaching boiling point.

But I'll do that now with the pot leak fixed.

Thanks for the advice!!!