Page 1 of 3

09/16 - Cast Bullet Designations

Posted: 30 Aug 2016 18:09

by 62chevy

daboone wrote:Well wait a minute...... er, ah, well I was hoping there would be tons of member's suggestions, hoping really hoping.

Wait a minute I just got here today so all ain't lost. I'd like to see a on bullet weight or how someone like RD comes up with it and what alloy it is based on. Lyman is based on #2 alloy but what about Lee or even RD's molds.

Re: 09/16 - Cast Bullet Designations

Posted: 31 Aug 2016 07:45

by RBHarter

That's simple .

Lyman Lee and RCBS are based on #2 or equivalent. NOE and Heavy Metal are based on typical WW . LBT , Accurate and Mountain Moulds allow for an alloy call .

Re: 09/16 - Cast Bullet Designations

Posted: 02 Sep 2016 14:08

by Ranch Dog

62chevy wrote:daboone wrote:Well wait a minute...... er, ah, well I was hoping there would be tons of member's suggestions, hoping really hoping.

Wait a minute I just got here today so all ain't lost. I'd like to see a on bullet weight or how someone like RD comes up with it and what alloy it is based on. Lyman is based on #2 alloy but what about Lee or even RD's molds.

When I started ordering custom molds from Lee, I based the weight portion of the designation on Lyman #2 (original or a clone mix) as that is what I used. As I started selling the molds, I restated this and included a chart that indicated the estimated weight with different alloys.

Still a lot of customers just didn't read or get that alloy matters. They would call or write as to why the bullet dropped at XXX. Usually it was the wheel weight guys, I think when you start using something other than what fell off a car you get it. I was getting tired of the questions so I had a "shift" in my designations to reflect the weight of my designs in wheel weights.

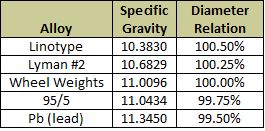

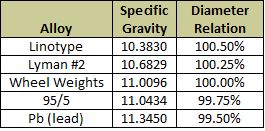

As a alloy gets heavier, the specific gravity of the alloy, it casts at a smaller diameter than lighter alloys because it simply isn't fluid enough to conform to the features of the mold. So, I started including the diameter delivered on my charts.

Lee faces the same issue and this is why you will see a difference talked about between their designation and the drop. Their designations are based on 95/5 (Pb/Sn). Pb is lead, not wheel weights, with a specific gravity greater than lead but when the 5% of tin is added with it's extremely low SG (7.3370) bullets molded with wheel weights in a Lee mold will always drop heavier, a common, unthought out, and unjustified complaint against the Lee molds.

Not only does delivered weight change with the SG of an alloy when applied to the fixed cavity of the mold, diameter does as well. There is the fluidity of the alloy, how well it conforms to the mold cavity, and shrinkage.

Note: The specific gravity of wheel weights is an estimate, in reality it is all over the map. The only way to know for sure is to measure it.

Note: The specific gravity of wheel weights is an estimate, in reality it is all over the map. The only way to know for sure is to measure it.

Re: 09/16 - Cast Bullet Designations

Posted: 02 Sep 2016 16:14

by 62chevy

RD that is about what I thought was going on with molds but just not sure. All my Lee molds drop heavy but one and that one is around 10 to 12 grains light. It's just a plinking bullet so never bothered to send it back to Lee.

Re: 09/16 - Cast Bullet Designations

Posted: 02 Sep 2016 16:44

by GasGuzzler

We don't all have 5K pounds of lead to choose from. I am fortunate enough to get WW free. I myself don't get Sn for free so I usually skip it except adding solder that contains Sn.

Good thing I don't care about dropping a couple grains light or heavy as long as they're close enough to put into groups.

I guess we all make of it what we want too. Some people think they're born to whine.

Ha!

Re: 09/16 - Cast Bullet Designations

Posted: 02 Sep 2016 19:29

by larryw

mikld wrote:Nope, not me, I'm innocent! I participated in the "Question of the Month", but did not originate it. Off hand I can't remember the feller's name...

I can't remember him either,.??

Re: 09/16 - Cast Bullet Designations

Posted: 03 Sep 2016 07:37

by 62chevy

GasGuzzler wrote:We don't all have 5K pounds of lead to choose from. I am fortunate enough to get WW free. I myself don't get Sn for free so I usually skip it except adding solder that contains Sn.

Good thing I don't care about dropping a couple grains light or heavy as long as they're close enough to put into groups.

I guess we all make of it what we want too. Some people think they're born to whine.

Ha!

I have over a hundred pounds of lead but most of it has been turned into bullets and what I do have left will get turned into more bullets this fall as the temps cool off. That is close to 4000 bullets for me and some would have that gone by Spring but should last me a couple of years.

Re: 09/16 - Cast Bullet Designations

Posted: 03 Sep 2016 16:54

by Old Scribe

I use 98% WW when I cast, except for my front suffers where it's pure Pb. I'm not too concerned with dropping a few grains as long as it's consistent. I am more interested in the diameter.

Re: 09/16 - Cast Bullet Designations

Posted: 03 Sep 2016 20:09

by Ranch Dog

Old Scribe wrote:I use 98% WW when I cast, except for my front suffers where it's pure Pb. I'm not too concerned with dropping a few grains as long as it's consistent. I am more interested in the diameter.

The heavier the SG of the alloy, the smaller the diameter. If the bullets start coming up short (under diameter) add tin.

One thing that me haven't mentioned is casting temperature with the aluminum mold. If you consider your alloy as fixed, your not going to add anything else, and your bullets are under diameter; add heat until the aluminum expands enough to give you the desired diameter. If your bullets are dropping too large in diameter, operate the mold at a minimum temperature for smooth operation to decrease the molds expansion. The beauty of an aluminum mold.

Re: 09/16 - Cast Bullet Designations

Posted: 04 Sep 2016 03:47

by GasGuzzler

Good thinking. That kinda stuff helps new casters like me.