Lee Pro Auto Disk

-

jc676

- Posts: 4

- Joined: 28 Apr 2020 15:17

- My Press Choice: Progressive

- Location: NM

- Has thanked: 12 times

- Been thanked: 1 time

Lee Pro Auto Disk

Hi Guys. I'm new to the Lee forum but not to reloading. Been doing so since the '80s.

I just bought my first Lee Progressive Press, the Breech Lock Pro. I love the press! The brass dispenser works perfectly and with the Safety Prime I can see that a primer is being dispensed every time, something I've struggled with on my Dillon Square Deal B.

I do have one issue though and it has to do with the Pro Auto Disk. It functions fine...throws powder every time. Where I'm having a hard time is with how much different the powder charge actually is compared to what the little chart says is should be. I'm perfectly fine with +/- .1 on either side of the listed charge, but I'm getting way different charges.

Using Accurate #2 (my favorite powder) I had to bump up two disk numbers to get close to my desired charge. Accurate #5 was pretty much the same deal. When I went to load some .44 Magnums with 2400, I wasn't close to the recommended minimum charge of 18.2 grains using the largest disk hole available with the single disk system. The Pro Auto Disk was throwing an average of 16.0 grains. The only other powder I had that was semi-usable for the .44 Magnum was Unique. Again using the largest disk hole I was still around 2 grains below the recommended start load. I understand Unique is tempermental in any kind of powder measure and the weights thrown varied by +/- 2.5 grains. This seems extreme.

So my question to y'all is are there any tricks I'm missing? Could there be something wrong with the way I have the Auto Disk set up? I love this press but won't be able to buy another powder measure for a couple of months (fixed income). I want to use it to load .38 Specials, .44 Specials/Magnums.

Any help all would be greatly appreciated,

Thank you,

Jon

I just bought my first Lee Progressive Press, the Breech Lock Pro. I love the press! The brass dispenser works perfectly and with the Safety Prime I can see that a primer is being dispensed every time, something I've struggled with on my Dillon Square Deal B.

I do have one issue though and it has to do with the Pro Auto Disk. It functions fine...throws powder every time. Where I'm having a hard time is with how much different the powder charge actually is compared to what the little chart says is should be. I'm perfectly fine with +/- .1 on either side of the listed charge, but I'm getting way different charges.

Using Accurate #2 (my favorite powder) I had to bump up two disk numbers to get close to my desired charge. Accurate #5 was pretty much the same deal. When I went to load some .44 Magnums with 2400, I wasn't close to the recommended minimum charge of 18.2 grains using the largest disk hole available with the single disk system. The Pro Auto Disk was throwing an average of 16.0 grains. The only other powder I had that was semi-usable for the .44 Magnum was Unique. Again using the largest disk hole I was still around 2 grains below the recommended start load. I understand Unique is tempermental in any kind of powder measure and the weights thrown varied by +/- 2.5 grains. This seems extreme.

So my question to y'all is are there any tricks I'm missing? Could there be something wrong with the way I have the Auto Disk set up? I love this press but won't be able to buy another powder measure for a couple of months (fixed income). I want to use it to load .38 Specials, .44 Specials/Magnums.

Any help all would be greatly appreciated,

Thank you,

Jon

- GasGuzzler

- Moderator & Supporter

- Posts: 2040

- Joined: 26 Jan 2016 22:39

- My Press Choice: Turret

- Location: Cooke County, TX

- Has thanked: 330 times

- Been thanked: 500 times

Re: Lee Pro Auto Disk

Unique meters well in nothing.

That being said, what are you using to compare the disk drop to? Could the other scale be off?

I had four disk machines at one point (because I bought RD's then sold them to go to the drum) and didn't see much variance between published weight and the cavity to use. Some of the issue is how Lee determines the hole to use. They use VLD (I think that's it) so the age, lot number, relative humidity, etc. all play a part.

RD will come long and likely explain this better than me and likely also say how much better the Auto Drum is.

That being said, what are you using to compare the disk drop to? Could the other scale be off?

I had four disk machines at one point (because I bought RD's then sold them to go to the drum) and didn't see much variance between published weight and the cavity to use. Some of the issue is how Lee determines the hole to use. They use VLD (I think that's it) so the age, lot number, relative humidity, etc. all play a part.

RD will come long and likely explain this better than me and likely also say how much better the Auto Drum is.

__________________________________________________________________________________________

I've always been crazy but it's kept me from goin' insane.

I've always been crazy but it's kept me from goin' insane.

- Macd

- Supporter

- Posts: 1009

- Joined: 16 Oct 2017 16:12

- My Press Choice: Single Stage

- Location: Far East

- Has thanked: 362 times

- Been thanked: 403 times

Re: Lee Pro Auto Disk

I always have to up disk size to get near the weight specified in the tables. RD's database is more accurate.

-

jc676

- Posts: 4

- Joined: 28 Apr 2020 15:17

- My Press Choice: Progressive

- Location: NM

- Has thanked: 12 times

- Been thanked: 1 time

Re: Lee Pro Auto Disk

Gas & Mac, thanks for the replies. Is there a way to obtain RD's database? I guess I can always load the Magnums on my Lee Single Stage. Actually use very little of them, just in my Winchester 94AE, so if I could get info that gives a more accurate Disk Hole Number that sure would save me a lot of time.

Also, I did double-check my scale. I typically use a Dillon balance beam and I checked it against my RCBS Charge Master. Everything was copasetic.

Thanks again,

Jon

Also, I did double-check my scale. I typically use a Dillon balance beam and I checked it against my RCBS Charge Master. Everything was copasetic.

Thanks again,

Jon

-

horseman

- Supporter

- Posts: 999

- Joined: 09 Nov 2015 06:35

- My Press Choice: Single Stage

- Location: Washington State

- Has thanked: 37 times

- Been thanked: 274 times

Re: Lee Pro Auto Disk

What you're seeing with the disks is normal. Same thing happens with shot shell bushings when loading for shotguns. You probably have the VMD chart as it should come with the powder measure, but if you already know the amount the disks are "supposed" to throw you already know how that works. The best any fixed cavity powder dispenser can do is "close" to what "exact" charge you may want. There are a couple methods that guys have come up with to make a cavity "adjustable". Some have used tape in a larger cavity, some have drilled and tapped for a set screw in a large cavity for finer adjustment. Some just drill the hole bigger. I use the adjustable charge bar. Just turn the dial until I get what I want. I only use the vernier (?) on the bar to get me close. Most all think the Auto Drum is just great, I don't hold that particular opinion. It came close, but to "finicky" and to many "loose" tolerances for me. For pistol calibers, IMO, the Pro Auto Disk is a better measure. I have an Auto Drum sitting on the shelf.

Edit: I just went in and checked my disk set. According to the VMD chart 18.2 gr. of 2400 "should" be the 136 cavity, that threw over 17gr (I didn't write it down) but the 146 cavity (next in line on the disk) threw 18.5 and there is still a larger cavity on that disk so maybe check you disk numbers.

Edit: I just went in and checked my disk set. According to the VMD chart 18.2 gr. of 2400 "should" be the 136 cavity, that threw over 17gr (I didn't write it down) but the 146 cavity (next in line on the disk) threw 18.5 and there is still a larger cavity on that disk so maybe check you disk numbers.

- Ranch Dog

- Site Admin

- Posts: 6457

- Joined: 22 Jun 2013 17:16

- My Press Choice: Progressive

- Location: Inez, TX

- Has thanked: 1617 times

- Been thanked: 2850 times

Re: Lee Pro Auto Disk

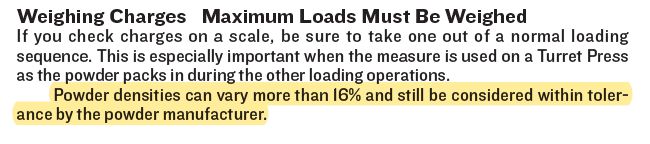

The bottom-line, when working with a fixed cavity, is knowing your powder. Powder manufacturers are not held too much of a standard, lot to lot, and bulk density varies. This note from Lee is with all their powder delivery tools.

What that means is that Lee used the stated bulk density of the powder to calculate what a specific cavity will deliver. The odds are greater than 5 to 1 that any given disk will provide the stated charge. Powder bushings used with other delivery systems are no different, but at least Lee's cavities are calibrated in cc's, which makes it easy to figure out what the bulk density of your powder is. Once you figure it out, write it on or label that number on the bottle or jug.

Lee uses the term, "VMD," which is "Volume Measuring Density." The math behind Lee's tables is:

All of Lee's current powder delivery tools use the VMD vs. CC math.

What that means is that Lee used the stated bulk density of the powder to calculate what a specific cavity will deliver. The odds are greater than 5 to 1 that any given disk will provide the stated charge. Powder bushings used with other delivery systems are no different, but at least Lee's cavities are calibrated in cc's, which makes it easy to figure out what the bulk density of your powder is. Once you figure it out, write it on or label that number on the bottle or jug.

Lee uses the term, "VMD," which is "Volume Measuring Density." The math behind Lee's tables is:

- CC/VMD = grains

- CC/grains = VMD

- Write that number on the jug!

- I use a Lee dipper that is appropriate for the powder, be it a pistol or rifle. You might not have the dipper set, but most of us have an appropriate dipper that came with a die set.

- I take ten samples, thirteen are better.

- I push the dipper into the powder and bring it out of the top of the container. It should have a "mound" on top. Cut the mound off by running a business card across the top of the dipper (I've learned something from over 50 years of using dippers accurately).

- Collet the 10 or 13 samples together. Weigh them together, and divide the weight by the number of samples. That is the average charge.

- Calculate the VMD by using CC/grains = VMD

- CC is the dipper used

- Grains is the average weight

- Use this VMD with any cavity to determine what charge will be delivered with your powder.

- CC/VMD = grains

All of Lee's current powder delivery tools use the VMD vs. CC math.

Michael

- Macd

- Supporter

- Posts: 1009

- Joined: 16 Oct 2017 16:12

- My Press Choice: Single Stage

- Location: Far East

- Has thanked: 362 times

- Been thanked: 403 times

Re: Lee Pro Auto Disk

Another factor is that even regular shaped powder doesn't stack like construction blocks in either the hopper, tube or the disk cup. Air takes up some of the volume. Some powders are worse than others in this regard. Drop tubes are used when filling cases to maximum to overcome some of the space between kernals etc. introduced when the powder flows in a more unrestricted way into the case. Tapping the powder measure or using a firm and consistent stroke helps. The Lee handgun powder through dies have a built-in bump that helps ensure the full charge powder gets into the case. One final issue is bridging of powder, kinda like two guys trying too get through a door at the same time, large stick extruded being a particular culprit. Takes place anywhere the powder flows through a narrow opening such as out of the powder measure, through a funnel or into a case. This is one reason I always tap the hopper body and use a good positive stop of the press handle. Everyone has experienced the PITA powder everywhere scene that happens when you move a case and the rest of the powder dumps.

- Ranch Dog

- Site Admin

- Posts: 6457

- Joined: 22 Jun 2013 17:16

- My Press Choice: Progressive

- Location: Inez, TX

- Has thanked: 1617 times

- Been thanked: 2850 times

Re: Lee Pro Auto Disk

I looked at my reloading software and see that I have 36 different containers of powder. Some might be of the same name, but a different lot. They total slightly over 99 lbs (the software reduces the volume of the powder for every load I build). I verify the individual containers VMD and record it. The maximum spread of all these lots against the powders stated density is 16.52%.

So, I'd call the claim in Lee's instructions valid.

So, I'd call the claim in Lee's instructions valid.

Michael

-

jc676

- Posts: 4

- Joined: 28 Apr 2020 15:17

- My Press Choice: Progressive

- Location: NM

- Has thanked: 12 times

- Been thanked: 1 time

Re: Lee Pro Auto Disk

Ranch Dog, thank you very much for all the information. I have some work to get done, for sure! Appreciate you (and the other guys too) taking the time for such a detailed explanation. As soon as I get an opportunity I'll get to calculating!!

Thank you,

Jon

Thank you,

Jon

-

horseman

- Supporter

- Posts: 999

- Joined: 09 Nov 2015 06:35

- My Press Choice: Single Stage

- Location: Washington State

- Has thanked: 37 times

- Been thanked: 274 times

Re: Lee Pro Auto Disk

RD, following your example, I just did a thirteen charge sample of Silhouette powder (Lee chart says vmd is .0796) using a 5cc dipper (only one I have) in my powder scale and came up with the average charge weight. Doing the math as prescribed I came up with a vmd of .07568. (My dipper "precision" probably had something to do with that and I would do it a couple times before using that number) So to further my understanding, I would then use this vmd number times actual charge weight (grains) wanted to find the correct fixed cavity (volume) for that amount. Dropping by volume vs weight. ??

Also, if this is a "preferred" or maybe "better" method of charging cases then why does Lee advise weighing charges at or near max..? Would that be because load manuals use powder charges by weight vs volume and the load manuals are tested as such. As I ponder this, it would seem that using a vmd number to a weight ratio (as in the Lee chart) would still be a better approach. My head hurts.....

Also, if this is a "preferred" or maybe "better" method of charging cases then why does Lee advise weighing charges at or near max..? Would that be because load manuals use powder charges by weight vs volume and the load manuals are tested as such. As I ponder this, it would seem that using a vmd number to a weight ratio (as in the Lee chart) would still be a better approach. My head hurts.....